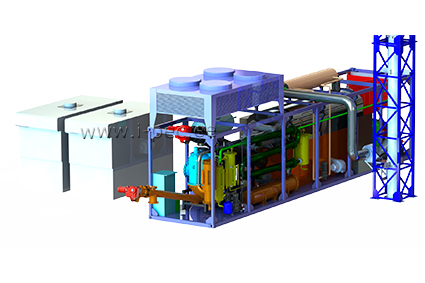

Continuous Thermal Decomposition Plant (TDP-2-500)

« Back to the listprocessing speed

qty of cycles of processing per day

tension

power consumption

INTENDED USE: Innovative low-temperature pyrolysis process for thermal decomposition of hydrocarbon-containing waste with the recovery of pyrolysis gas, liquid fuel oil, and biochar (carbon black).

SOURCE OF FEEDSTOCK:

— Industrial rubber goods, tyres

— Waste plastic, polypropylene bag (big bag), film

— Blend of polymers (PE, PP, PS)

— Lubricating and heavy oils, any type of solvents

— Oil sludge, drilling waste

* subject to provide a shredder machine

ADDITIONAL FEATURES:

- Thermal energy recovery – up to 60 kW (with an optional heat-exchanger (recuperator)

- Electric power generation up to 1 MW (with an optional microturbines)

BENEFITS:

- Reduction the burden on facility’s electric power supply

- Electricity power distribution to facility / field / locality

- Additional energy reserves in the case of emergencies

- Usage of the process products (gas and oil) as an alternative energy source

TDP-2-500 PROCESS DESCRIPTION

1. The source material is continuously fed into pyrolysis chamber from the hopper/by the pump.

2. The pyrolysis chamber is heated by the mixed fuel burner installed in furnace.

4. Liquid fuel is used for the plant startup. It is self-fed from fuel tank to the burner.

7. After the startup the burner capacity is lowered and heating is carried out on pyrolysis gas.

3. Vapor and gas mix is cooled in the condensation system, then in heat exchanger by recirculation.

6. Vapor and gas mix product is fed from the heat exchanger to the gas-liquid separator where flows are separated.

=> LIQUID FUEL is drained to receiver tank and then is directed to the microturbines

=> GAS is fed to the burners, the remaining amount of it is sent to the microturbines

7. DRY RESIDUE is discharged by screw conveyor to the air tight hopper, where it cools and further to the storage bin.